DRVZ Nozzle Check Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

DRVZ Nozzle Check Valve

Overview

The DRVZ Nozzle check valve features a contour design that perfectly conforms to hydraulics, achieving a streamlined waterway. Its internal fluid guide design ensures minimal pressure loss. Installed at the pump outlet, this Nozzle check valve quickly closes before backflow occurs, preventing water hammer, water surge noise, and destructive impacts. It achieves the goals of quiet operation, backflow prevention, and equipment protection, and is widely used in water supply and drainage, fire protection, HVAC, and industrial systems.

Features

1.Excellent noise reduction: Streamlined internal flow channel and short valve disc stroke enable quick closure when the pump stops, preventing loud water hammer and reducing flow noise for quiet operation.

2.Low pressure loss: Streamlined internal flow channel ensures smooth medium flow, minimizing pressure loss and energy consumption while boosting system efficiency.

3.Automatic operation + strong water hammer resistance: Auto opens/closes via medium pressure (no manual operation – opens on forward flow, closes on stagnation/backflow to prevent backflow); instant closure on pump shutdown effectively resists water hammer, protecting pumps and pipelines and extending equipment life.

4.Compact structure: Small, lightweight, and processable, with easy installation/maintenance, space-saving design, and adaptability to various environments.

5.Superior sealing: Composed of valve body, seat, flow guide, disc, bearings, springs and other key components; rational structure ensures excellent sealing, unidirectional medium flow and no leakage.

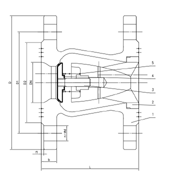

Dimensions & constructral diagram

DRVZ Nozzle Check Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Stainless Steel |

| 2 | Diversion Device | Stainless Steel |

| 3 | Shaft | 2Cr13 |

| 4 | Disc | Stainless Steel + EPDM |

| 5 | Spring | 304 |

Performance Specification

| Performance Specification | ||

|---|---|---|

| Nominal Pressure | 1.0/1.6 | MPa |

| Shell Test Pressure | 1.5/2.4 | |

| Seal Test Pressure | 1.1/1.76 | |

| Suitable Temperature | ≤80 | ℃ |

Specification and dimensions

| DN | L | D | D1 | D2 | n-d | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | ||

| 40 | 110 | 150 | 150 | 110 | 110 | 88 | 88 | 4-18 | 4-18 |

| 50 | 120 | 165 | 165 | 125 | 125 | 102 | 102 | 4-18 | 4-18 |

| 65 | 150 | 185 | 185 | 145 | 145 | 122 | 122 | 4-18 | 4-18 |

| 80 | 180 | 200 | 200 | 160 | 160 | 138 | 138 | 8-18 | 8-18 |

| 100 | 229 | 220 | 220 | 180 | 180 | 158 | 158 | 8-18 | 8-18 |

| 125 | 254 | 250 | 250 | 210 | 210 | 188 | 188 | 8-18 | 8-18 |

| 150 | 267 | 285 | 285 | 240 | 240 | 212 | 212 | 8-22 | 8-22 |

| 200 | 292 | 340 | 340 | 295 | 295 | 268 | 268 | 8-22 | 12-22 |

| 250 | 330 | 395 | 405 | 350 | 355 | 320 | 320 | 12-22 | 12-26 |

| 300 | 356 | 445 | 460 | 400 | 410 | 370 | 378 | 12-22 | 12-22 |

| 350 | 381 | 505 | 520 | 460 | 470 | 430 | 438 | 16-22 | 16-26 |